Steel Pail, is not a new package methodology. The plastic revolution happened after the Second World War. For a long period, buckets have been made of wood, iron metal, and galvanized ones. These traditional packaging materials have existed for over 2000 years.

Today tinplate steel buckets, the new miracle material of the modern world, offer a new cost-effective, reinforced, recyclable, rust and corrosion-resistive way to mass produce in industrial packaging. This new coating technology provides metal buckets a lighter weight than traditional wooden and iron ones and also gives external and internal protection for better duration.

By producing versatile containers in the most common sizes, tinplate metal buckets suppliers developed derivative peripheral products such as lug lids, bucket crimpers, bucket liners, lever lock rings, and more.

Last many articles we introduced plastic buckets such as 5-gallon cylinder plastic buckets, and square plastic buckets. let’s lead you to explore the benefits and characteristics of 5-gal cylinder metal buckets. It will help you choose alternative metal or plastic for commercial packaging.

What Is Tinplate Steel?

Tin refers to a metal element known for its corrosion resistance and malleability. According to these two main chemical advantages, it is perfect for welding and forming during the tinplate metal bucket production process.

However, tin cannot directly use to produce buckets virginal raw material. Common metal buckets are made of tinplate-coating steel. So tin-plating is a process of coating a thin steel sheet by dipping it in molten tin metal or electrolyte deposition.

Tinplate involves coating a base metal, often steel, with a thin layer of tin to protect it from corrosion and improve its appearance. Usually tinplate steel is used in manufacturing tin cans(small volume) and tin buckets (bigger sizes). Industries demand tin container to package food , beverage like concentrate juice, and tomato sauce, condensed milk, and other industrial applications such as paint, fuel, cosmetics.

Producing Article

Innopack® container and packing company creates robust, huge amounts of noncorrosive and nontoxic 5-gal tin buckets for common industrial needs. In the factory, steps of producing flow includes:

- Starts by collecting highquality UN-rated raw material from tinplate steel sheets.

- An effective cutting machine will cut areas in batches for your sized metal needed.

- Then the welding process is to create a cylinder containing capacity.

- Commercial painting your label, and logo textures on your metal buckets.

- After that, the forming machine utilizes hydraulic pressure to create the perfect shape of a metal bucket.

- Meanwhile, the bottom cover sealing provides a strong and leaking-proof structure. If needed we can offer top cover sealing.

- After product testing, we directly package and ship to your worldwide destinations on time.

5 Gal Metal Bucket Across Industries

- Paint and coatings industry:5 gal paint buckets with lug lids (flour cover) are the most common and ideal containers for storing and mixing paints, auto paint, wood marking paint, epoxy floor paint, wall paint, varnishes, and coatings.

- Chemical industry: attach a lever lock ring closure cover that can safely contain hazardous materials, chemicals, and solvents, especially when leaking-proof transporting.

- Agriculture:Versatile solutions for storing fertilizers, seeds, and animal feeds, better come with FDA Bucket Liners can prevent pollution, and maintain reusable condition.

- Construction: Essential for transporting and storing construction materials like adhesives, sealants, and lubricants, the metal wall is strong for using.

- Automotive: Used for storing oils, lubricants, and automotive fluids. Perfect combined lever action pump and air-tight lid with spout.

Advantages of tinplate steel buckets

Why do many people use buckets made of steel? Please continue to read, here are the answers that may clarify the advantages of why you need to pick up a metal steel tin bucket.

- Durability: when faced with higher temperature ingredients or a fire, a tinplate metal bucket won’t melt. The inative molecular structures will prevent itself turns to chemical reactions and transfer to other phases. For spaying additional rust inhibitor layer. It protects your buckets and maintains good.

- Corrosion resistance: protective properties of epoxy or phenolic resin internal lining, provide sensitive products remain stable and non-corrosive to buckets.

- Versatility: earlier we expressed how these buckets can be adapted to various tasks and industries, providing cost-effective solutions.

- Storage recommendations to prevent corrosion and damage. Store all metal tin buckets in a clean warehouse and better at a dry room temperature. If possible let innopack® stretch film to make a packaging service on a plastic or wooden pallet before delivery. It is a good idea to protect the shining surface finish.Recyclable: eco-friendly nature of metal tinplate steel, which can be recycled repeatedly without loss of quality. Experts have expressed that it can take up to 450 years for a plastic container to degrade in a landfill, while tinplate steel tends to break down in around 50 years.Innopack® CO., Ltd. consistently uses recycled tinplate and plastic for packaging manufacturing. That reduces much more energy usage when compared to creating new material. We comply with sustainable development to save a beautiful planet –“Earth”.

Tips for prolonging the lifespan of metal tinplate steel buckets

Rust is the most important enemy for all metal bucket users. How to maintain using condition of the metal bucket? Next paragraph we will make some experienced suggestions for our clients.

- Avoid wet or soaked environments.A good environment where you store buckets can also affect the duration of metal buckets. Don’t expose buckets to high humidity( above 60%) or rain.

- Storage recommendations to prevent corrosion and damage. Store all metal tin buckets in a clean warehouse and better at a dry room temperature. If possible let innopack® stretch film to make a packaging service on a plastic or wooden pallet before delivery. It is a good idea to protect the shining surface finish.

- Inspection for dents, rust, and other signs of wear. 5- gal Bucket liner is another meaningful plastic packaging accessory that creates seamless, durable, FDA-approved(HDPE), lip attachable for reducing the time and expense of cleaning and replacing buckets.

- Better to stack up metal buckets for Nesting.Innopack® supplies 5-gal (20L) open-head tin buckets which can perfectly stack together for transporting and storing. Not only for saving space to lower transport costs and maximize space saving at your warehouse. It reduces the contract areas of your buckets to the atmosphere.

Specification

- SIZE RANGE: 5 Gallon (1-7 gal available)

- Height: 340 mm (the height is adjustable for the customer’s request)

- Top Diameter: ø297mm

- Bottom diameter: ø276 mm

- Weight: 1188g

- Color: Black Coating, CMYK printing, can print your design (Logo)

- Material: 26 gauge Tinplate steel/ stainless steel

- Lining: Gold phenolic lining /Epoxy lining/Rust inhibitor

- Lids: Lug lids/ lever lock ring

- Capacity: ≤ 80 lbs

- pH Range: 0 – 7.0

- Specification: UN Rated/ not UN rated.

- Temperature: -30° to 250° F

Future Packaging

Tinplate represents one of the important methodologies in the packaging industry. A thinner layer coating on steel provides corrosion resistance and is often used in painting, food, and aerosol containers. Innopack® container supply company is confident in providing high-quality tinplate buckets to meet the growing needs of our customers.

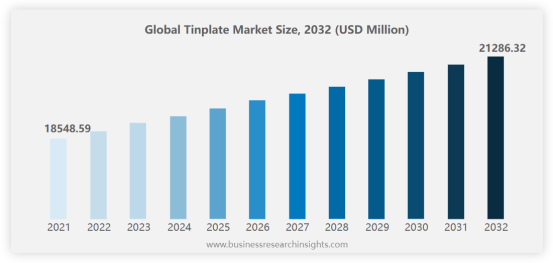

A report from Business Research Insights shows the fact of increasing trend in tinplate .“Global tinplate market size was USD18548.59 million in 2021 and market is projected to touch USD 21286.32 million by 2032 at CAGR 1.26% during the forecast period.” (Tinplate Market size, share, growth..DEC,2023, Report ID: BRI110250)

Tinplate steel buckets reduce negative effects on the environment because of their recyclable use.It also helps to extend content’s shelf life, better durability, corrosion resistance, and leak-proof for their packaging and storage needs.

Please contact us today to know more information about 1gallon-7gallon range size metal tinplate steel buckets. We‘d like to offer you a lower-price plastic and metal container packaging solution.

- Storage recommendations to prevent corrosion and damage. Store all metal tin buckets in a clean warehouse and better at a dry room temperature. If possible let innopack® stretch film to make a packaging service on a plastic or wooden pallet before delivery. It is a good idea to protect the shining surface finish.Recyclable: eco-friendly nature of metal tinplate steel, which can be recycled repeatedly without loss of quality. Experts have expressed that it can take up to 450 years for a plastic container to degrade in a landfill, while tinplate steel tends to break down in around 50 years.Innopack® CO., Ltd. consistently uses recycled tinplate and plastic for packaging manufacturing. That reduces much more energy usage when compared to creating new material. We comply with sustainable development to save a beautiful planet –“Earth”.