When the concept of in-mould labelling (IML) appeared during the 1970s, it marked a significant breakthrough in the realm of labelling methodologies. Since then, this technique has evolved continuously, garnering substantial application in recent times.

What Is In-Mould Labeling

In this process, a pre-printed polypropylene (PP) label is inserted into the mould, where the molten PP merges with the label during the curing phase, resulting in a visually appealing and resilient finish. Consequently, the label seamlessly integrates into the product, becoming an intrinsic component.( For more process details of IML, please read our previous blog news:“How In-Mold Labeling Process”)

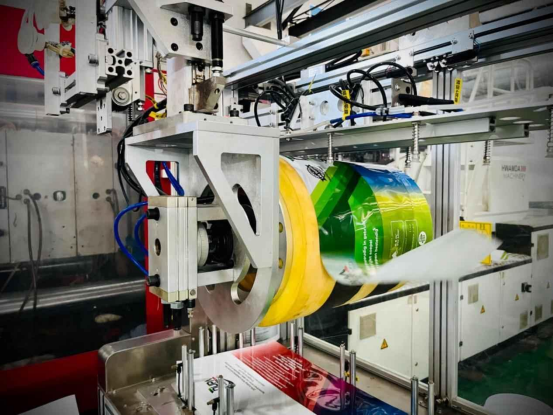

(Photo: Innopack® fully automatic In-mould Labeling for plastic buckets)

Advantages

Innopack® Plastics Bucket Manufacturer stands out as a distinguished in-mould labelling expert in worldwide, providing tailored solutions for a diverse array of plastic goods. For enhanced labelling efficacy for your merchandise, exploring in-mould labelling is highly recommended.

Outlined below are five key benefits of in-mould labeling:

- Optimization:

Incorporating in-mould labelling not only reduces wastage but also streamlines the production process by eliminating post-labeling tasks, thereby saving both time and labor costs.

- Versatility:

A notable advantage of in-mould labelling lies in its adaptability to various shapes. Whether crafting tubs, containers, glasses, caps, or boxes, these labels can be seamlessly applied to all forms.

- Quality:

In-mould labeling ensures impeccable graphic precision, positioning it as the premier choice among its counterparts. Moreover, its seamless integration with the product imparts an organic aesthetic appeal.

- Reusability:

In scenarios where in-mould labels share the same composition as the containers, and the containers are recyclable, the labels themselves become recyclable, fostering sustainability.

- Durability:

In-mould labels exhibit remarkable resilience against wear and tear, and scratch resistance, enduring rough handling with ease. Moreover, they can withstand the rigors of industrial washing and high-temperature processes without deterioration.

Is In-Mould Labeling Right For You?

Compared to traditional labeling services, you need to know if IML fits your business. Even though IML has many benefits, you always consider the most cost-effective decision on labeling as the best option for you depending on your needs. Here are some factors to think about if IML is the best labeling option for your packaging:

Requires minimum order quantity

Minimum order quantities commonly require higher in-mould labeling than traditional labeling methods such as silkscreen and heat transfer printing, etc. Due to a unique mold design and machinery, installation is all customized. In-mold labeling is an economic method because the cost per container is cheaper in automatic mass injection molding production quantities(OEM& ODM).

Increased prepare times

According to IML requires specific mold design and set-up time for injection molding machines with IML Robot arm and film stages. It is an advanced live production system This is the on-the-spot manufacturing plus the just-in-time printing manufacturing process, so we can’t use any prefabricated stock. I will recommend that you reserve the typical amount of up-front design time for preparation and you’ll have tons of time to make the final result on time.

Combined with container Production

IML(in-molding label) must merge with the injection molding plastic container production. It can’t be dependently labeling the empty buckets, jars, bottles, or boxes. So if you have a demand for bulk production of plastic containers. It will be a fantastic add-on option for bucket decorating while making a good-quality plastic bucket.

(photo: In-Mould label must merger with injection molding machine)

In-Mould Labeling Applications

Personal care products: shampoo bottles, deodorants and soaps, tubs.

Food packaging: ice cream tubs, yogurt containers, butter buckets & takeaway containers.

Supplement packaging: protein powder jars and containers, vitamin jars.

Cosmetic packaging: sunscreen, lotions, and liquid makeup bottles.

Household products: bulk cleaning supplies, laundry detergents, fabric softeners.

Industrial Packaging: paint buckets, adhesive buckets, and cement containers.

In-mould labels find application across diverse industries such as food, beverages, cosmetics, healthcare, and pharmaceuticals, catering to a wide spectrum of products. Should you aspire to achieve flawless resolution for your products through in-mold labelling, consider engaging with Innopack® Plastics. As a prominent manufacturer of plastic injection-molded products in China, Innopack® Plastics offers an extensive range of 5-gallon Plastic Buckets & Pails, Gamma Seal Lids, Ice Buckets, Paint Buckets, Fertilizer Buckets, and plastic accessories.

We focus on making buckets, pails, and packaging for consumer goods. We offer custom molding solutions at affordable prices to our customers. Connect with industry-leading professionals to procure top-tier custom molded containers.