In packaging and manufacturing plastic buckets, containers or other accessories, we commonly discuss two separate industrial processes of producing and decorating. Traditional decorating companies in the past had difficulty branding their pails or bottles. This was because of their lack of durability, low quality, and slow production time.

In-mold labeling (IML) started in blow molding packaging in the late 1970s. This method helped plastic manufacturing and packaging industries by combining production and labeling, saving time and steps. Recently, a new labeling technology has become popular worldwide. Industries such as paint, chemicals, oil, daily necessities, food, and pharmaceuticals are using it.

So what is IML (in-mold labeling)?

IML (In-Mold Labeling) is a way to decorate molded plastic by putting a film inside the mold during injection. The logo is printed on the plastic product, along with the label. The colors are printed directly on the plastic items. The logo is firmly embedded on the surface. The label and plastic products are on the same surface.

Paper and Plastic film are two common materials for label-making. Water or moisture can deform the paper, reducing its usefulness. However, it has the advantage of not causing static interference, preventing label loss when placed in a mold. Paper is also not compatible with plastic buckets and is difficult to recycle. Nowadays, plastic film in-mold label materials are generally used in the packaging industry.

The film material can be stretched, squeezed, and reshaped to fit plastic items. When applied to products, it molds perfectly to their shape. The label stays smooth and doesn’t wrinkle when attached to a plastic pail.

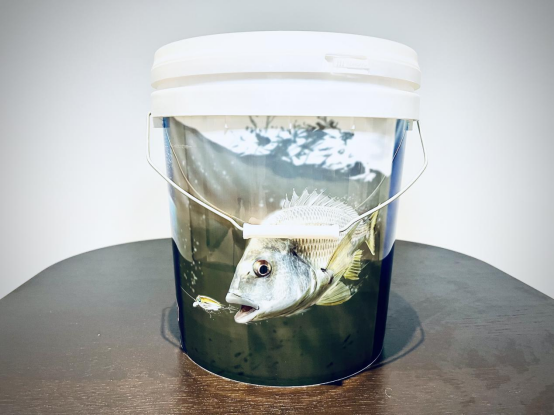

The film material used for printing labels is bright, has a strong 3D effect, and has better color quality than paper. The film material used for printing labels is bright and has a strong 3D effect, and it also has better color quality than paper. This material is ideal for high-quality printing. It works well for various products, especially those made of PE, PP, or a combination of both.

Plastic and Image are One

When the hydraulic clamp closes, it ejects the melted plastic into the mold at a temperature between 200℃-430℃. The label adhesive on the plastic bucket prototype melts and combines with the plastic in the mold.PP or HDPE synthetic paper is treated on the surface. It is then coated with a special hot melt adhesive on the back. This creates a special label paper for printing trademarks.

How In-Mold Labeling Process:

- Preparation of labels

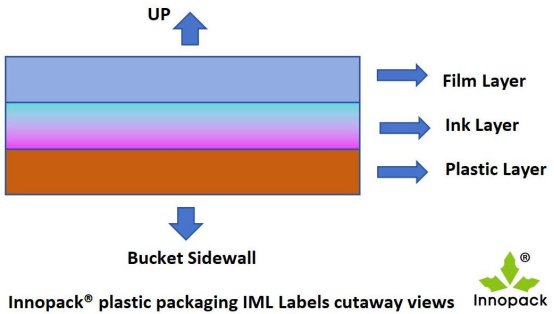

Let us talk about the material structure of the in-mold label is composed of a printing surface, an intermediate layer, and an adhesive layer. An extremely easy concept of IML film is a ‘sandwich’ with 3 layers. The function of the printing surface is to accept ink and form color graphics; The middle layer keeps the printing surface stiff and transparent. It also prevents deformation during printing and high temperatures. Additionally, it ensures accurate overprinting. The sticky layer melts in heat, making the label and plastic container bond together securely.

- Integration of labels into the mold

The electrostatic die suction method requires specific physical properties for the equipment and labels used in in-die labeling technology. The electrostatic die suction method needs certain physical properties for the equipment and labels used in in-die labeling technology.

An electrostatic discharge system is necessary to quickly apply a uniform charge to the label. A mechanical arm is required to attach the label to the injection mold cavity at zero potential. Indeed, the slippability ensures the smooth separation of labels and a smooth printing process.

- Injection molding and label fusion

Plastic resins are heated and melted in the injection molding machine’s barrel. After the mold is closed, melted plastic will be ejected through the nozzle into the mold cavity. Buckets will be shaped and the bottom layer of Labels films will be adhesive melted and attached.

Label fusion happens during the water cooling process, IML films stack on the bucket sidewall forever. The in-mold labeling process is the same as in injection molding production.

- Final product removal and finishing

After the Molding chamber opened again, the IML decorating was completed with bucket production. At the same time, you can take off manually or the robot arm automatically removes the plastic buckets from the mold. The QS manager will double-test and check the logo and image to ensure they are labeled correctly on the bucket sidewall.

Advantages of In-Mold Labeling:

- Smooth Hand touch feel:Unless thermal transfer printing and screen printing, IML printing doesn’t have edge joints or gaps. You can feel what an original plastic bucket sidewall feels.

- Cost reduction:can be achieved by using multiple surface effects on one product. This allows for fewer mold sets to be used, which in turn lowers production costs. Additionally, it makes assembly more efficient.

- Wear resistance: surface wear resistance, scratch resistance, surface hardness

- Durable: Decorative pattern hidden never fades, key life of 5 million times

- Effect pigmentation: glossy appearance, bright color, beautiful pattern

- High definition:HD image, Bar codes, contexts, and designs printing super clear

- Waterproof:waterproof, moisture-proof, fingerprint-proof

- Environmental protection:the ink ingredients do not oxidize, are non-volatile, and meet environmental requirements.

- Covered bad bucket appearance: injection molding without clamping water lines/welding lines/flow marks

- Recyclable:materials like PP, ABS, and PE can melt together. You can grind buckets with IML labels into flakes and reuse them as raw material.

The Comparison Of Printing Technology

Innopack® plastic container packaging and manufacturing helps over 2000 customers in professional plastic buckets and accessories brand and commercial decorating. According to our service experiences, here is a technology comparison shown below:

| Performance | Screen Printing | Heat transfer | In-Mold Labeling |

| Scratch resistance | Good | Excellent | Excellent |

| Back light | Good | Good | Excellent |

| Graphic Solution | Excellent | Excellent | Excellent |

| Effect Pigmentation | Good | Good | Excellent |

| Process automation | Good | Excellent | Excellent |

| Process Speed | Good | Excellent | Excellent |

| Small Production | Excellent | Good | Excellent |

At Innopack, we provide a fast and cost-effective packaging solution. We automate the process of labeling plastic buckets with in-mold labeling technology. This allows for efficient and accurate labeling of products. Our system helps streamline the packaging process and saves time and money for businesses. Unlike traditional packaging decorating, Innopack® in-mold labels presents high-definition, waterproof, colorful images and product information in our range-sized products. If we can be of further assistance please do not hesitate to contact us.