Transparent plastic buckets nowadays have become a worldwide popular packaging solution. Clear plastic buckets are strong and safe for food.

They are also affordable and can be customized. Because of these features, many industries use them. These industries include manufacturing, car washing, agriculture, food processing, and household goods.

As the world’s leading supplier of transparent car wash buckets, let me show you a world of clear plastic buckets.

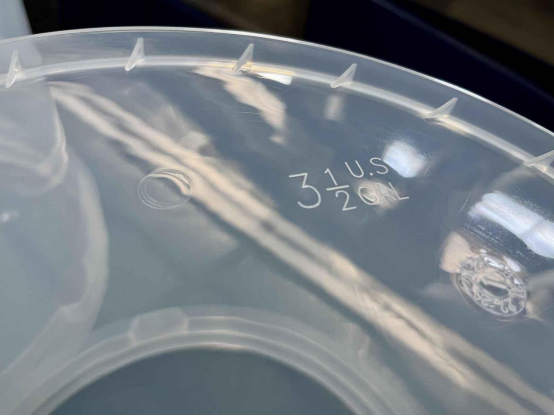

(photo: bottom of Innopack® manufactured 3.5 gal transparent plastic buckets)

Factors Affecting Plastic Bucket Transparency

Transmittance

The influence of light transmittance is divided into light reflection and scattering. When the reflected light is relatively small, it means that when the light is injected into the plastic buckets, it is not blocked too much, its light transmission rate is large, and the transparency rate is high.

The scattering of light is that the light incident on the plastic bucket surface, neither through nor reflected and absorbed a part of the luminous flux, its proportion is relatively small. So a good plastic bucket needs to reach both less light reflection and low scattering. In easy words, a plastic bucket looks as clear as glass.

Refractive Index

Refraction is the difference between the direction of incoming light and that of incoming light. For example, a resin used as a lens cap is expected to have a higher refractive index.

As a result, the greater the refractive index, the higher the density. The refractive index measures how light bends when it hits a material. For example, when sunlight hits a bucket’s wall, some light can’t pass through and instead bends back.

Haze

Haze, also known as turbidity, can measure the degree of opacity or opacity of transparent or translucent materials and indicates scattering. Haze (fog-like) is light scattering from the internal or external surfaces of the material which will cause a cloudy appearance in a plastic bucket. If you are interested in translucent plastic buckets, please read our previous blog news: “ Trust Building Packaging: 5L Translucent Plastic Buckets.” Innopack® recommends a good transparent plastic bucket that has a haze measurement of no more than 2%.

The above is the introduction of Innopack® Transparent Plastics. In conclusion, like glass, a good transparent material should let in a lot of light. It should have a low refractive index and a low haze measurement.

To distinguish whether the transparency of the plastic mainly depends on the type of plastic, and then analyze its influencing factors.

The Advantages Of Clear Plastic Buckets

(photo:Innopack® bulk oem clear buckets production)

Visibility

Transparent containers serve as an exemplary solution for discerning individuals seeking to identify their stored possessions effortlessly. They provide clear visibility that dark or colored containers cannot match. This helps prevent mixing up dangerous and safe items. It is an important way to avoid poisoning and other safety problems.

Moreover, these transparent vessels allow users to accurately assess inventory levels, ensuring that no items are inadvertently hoarded or neglected. A mere glance can reveal whether supplies are dwindling, enhancing both time management and operational efficiency. This practice not only conserves financial resources but also promotes environmental sustainability by curtailing waste—be it food, materials, or other perishables.

Organizing

The inherent transparency of these containers significantly aids individuals in managing their spaces. The lucidity afforded by clear containers empowers users and organizers alike to organize which items warrant retention and which should be grouped together. This straightforward yet effective methodology cultivates a sense of joy and order in one’s life.

Protection

A robust tamper-evident design hinges on immediate visibility. This feature allows individuals to swiftly ascertain whether an item has been compromised, eliminating the need for exhaustive inspections. Such awareness prompts users to either forgo the tampered product or conduct a cursory examination to ascertain the nature of the tampering.

Clear containers excel in this regard, as their transparency provides instant recognition of any alterations. This dual-functionality not only alerts users to potential hazards but also ensures that the contents remain safe for consumption, thereby fostering a heightened sense of security.

Customize Labeling

The exposure of a brand is as important as the product itself, and customers must first see your packaging before they go near it. Whether it is a cylindrical, square, rectangular, or oval plastic bucket, you can complete the printing of LOGO through screen printing, in-mold labeling (IML), and thermal transfer printing.

Here are a few tips: Don’t print too complicated patterns and text on a transparent (clear) plastic bucket. Otherwise, customers can focus on your pictures and texts when the background is not unique colors. Try a simple designed logo with one to three colors. Remember the purpose of using transparent plastic bucket packaging that to present what you contain inside the clear plastic bucket.

Clear Plastic Vs. Clear Glass

Both clear glass and clear plastic containers possess distinct characteristics and applications, each offering unique advantages. For instance, glass containers are generally more amenable to recycling, as their materials can be reconstituted with relative ease. In contrast, plastics undergo a more complex series of evaluations before they can be recycled.

Using Plastic buckets to replace glass containers, which is safer for packaging. While glass may appear robust, it is inherently fragile; upon breaking, it can shatter into perilous shards capable of inflicting injury. Conversely, clear plastic containers exhibit greater resilience and flexibility, boasting a higher tolerance for impact.

Economic consideration is playing another key role in the market. As we know, the plastic buckets are much lighter than other materials. Compared to glass containers, the clear plastic bucket is cheaper on its cost. Save costs means more profits.

(photo: Innopack plastic buckets manufacturer’s workshop)

Innopack® plastic buckets manufacturer

Innopack® uses the best-crystalized plastic materials (PP/HDPE) to make high-quality clear containers. such as 3.5 gallon or 5 gallon car wash buckets, 20L heavy-duty clear plastic buckets, etc. We offer transparent, translucent, or opaque options.

Whether you need sizes from 1L to 30L or 1 to 7-gallon buckets, we are here to help you. With 27 years of experience in injection molding OEM and ODM services, serving more than 130 countries and zero complaints.