In recent years, the worldwide market for baking cream was estimated to be worth roughly $3.5 billion. It is expected to experience consistent growth, with projections suggesting it could reach a value of about $5 billion by 2026.

The demand for baking cream in North America is a large part of the global cream market. Europe follows closely behind. The Asia-Pacific region is experiencing swift expansion due to shifts in eating patterns and increasing disposable income.

There has been a significant rise in home baking and increased awareness of healthy food consumption. Health-conscious consumers are driving demand for organic and plant-based (vegetable) alternatives.

Companies are increasingly prioritizing product innovation, encompassing variations, tastes, and packaging. Today, I’d like to introduce you to an economical plastic container designed for baking cream. It’s simple to manufacture in large quantities and features excellent branding on the containers.

(Photo: Innopack ®OEM served 10 Litre and 5 Litre Plastic buckets)

The Advantages of Plastic Buckets in the Cream Industry

Lets start with a simply question, why a plastic buckets becomes more like to carry backing cream in food industry? I analyzed following advantage you might find the answers from.

- Easy Access: 5L / 10L plastic bucket owns a wide opening which allows for easy scooping and pouring. It is convenient for both manufacturers and consumers to use the cream without spills or mess that is making it more user-friendly.

- Efficient Filling: During production, a wide opening facilitates fasterand more efficient filling processes, plastic bucket can reduce bottlenecks in packaging lines. With a tear tap lid provide a tamper-evident for customers.

- Improved Mixing: A wide opening helps mix a cream easily with other ingredients. This makes blending simple and effective. Wide open buckets can hold many tools, like spatulas or ladles. This is very helpful in commercial settings for mixing or serving. It is compatible with various dispensing and mixing equipment, facilitating smooth operations in commercial kitchens or factories.

- Reduced Risk of Contamination:A wider opening can help minimize the risk of contamination during filling and dispensing, as it’s easier to control the environment around the opening. A seamless bucket body with air-tight plastic lids is perfectly protected from air contact.

- Storage Efficiency:Wide open head buckets can be stacked or stored more easily, optimizing space in warehouses or refrigerators.

- Visibility:The larger opening allows for better visibility of the contents, helping users quickly assess the quantity remaining and plan for refills. It help to contributing to better marketing

- User-Friendly Design:Attached with steel wire handle, The wide opening contributes to an ergonomic design, making it easier for users to handle and manage the bucket.

- Ease of Cleaning:A wide opening allows for easier cleaning and maintenance, ensuring that all residue can be removed effectively, which is crucial for food safety.

- Temperature Regulation: The design can help with air circulation, reducing heat build-up during storage and maintaining the cream’s quality.

- Customization Options: A larger surface area around the opening can accommodate more elaborate labeling or branding, enhancing marketing opportunities.Innopack® provides professional Heat Transfer Printing & in-mould labeling.

- Reduced Waste: due to a seamless and flat bottom at bucket and a wide opening.The easy access minimizes the risk of cream being left in the container, leading to less waste and better cost efficiency for manufacturers.

- Visual Appeal:A wide opening allows for attractive presentation of the product, especially when used in display settings, contributing to better marketing.

- Safety in Handling:a Plastic handle or metal handle with A wider opening reduces the risk of accidents during use, such as dropping or spilling, as it allows for more controlled pouring.

- Robust material: Injection mold producing by using high-quality HDPE & PP polymer compounds.The 5L and 10L plastic buckets have strong walls that resist impact. They are designed to prevent deformation. This makes the buckets durable and suitable for long-term use. They are also reusable. and recyclable).

- Food Graded: plastic buckets are safe and resistant to corrosion. They come in 5L and 10L sizes. These buckets are used in many food industries, such as cream, ice cream, oil, and wheat. Alwayscheck if the bucket meets FDA, HACCP, and local government standards.

Heat Transfer Printing: A Cutting-Edge Solution

Heat Transfer Printing labels eliminate the need for wet inks and solvents, thereby simplifying the printing process within a production facility. They can be used in conjunction with an injection molding machine and a heat transfer printer, which applies a dry, pre-printed image. There’s no need for any pre or post-treatment. This method allows for instant printing of high-definition images, logos, text, and nutritional information directly onto the wall of a bucket.

The process is automation-friendly and typically faster than other printing ways. Colors are applied all at once. The image feels dry to the touch right after application. Thus transfer thermal printing is a great and fast labeling technology that you don’t have to wait for it to fully dry before moving on to the next step.

(photo: Innopack® heat transfer printing customized logo and label on bucket)

Automation and Robotics in Manufacturing

In China, there is a plastic production company INNOPACK®, as a plastic container manufacturing packaging industry leader, in the past 27 years, it has continuously innovated, upgraded automation, improved production capacity and quality, and won customer recognition in more than 130 countries and regions, more than 30 injection molding machines. To meet any requirements of customers for product packaging, from design, to mold manufacturing, production, printing, packaging, transportation, every link is carried out by experts with more than 20 years of experience.

The business scope includes full-size plastic buckets and pails, drums, LIDS, handles, decorating. Through conveyor belts and robotic arms, INNOPACK has achieved great success in reducing manual errors and improving production efficiency, and has once again increased the delivery speed of products in the past year.

10 Baking Cream Brands Recommends

- Land O’Lakes– Known for its butter and dairy products, including heavy cream suitable for baking.

- Dairy Farmers of America– Offers various cream products, including baking cream under different regional brands.

- Whipping Cream (Califia Farms)– Popular for plant-based cream alternatives, great for vegan baking.

- Lactaid – Known for lactose-free products, including cream, catering to those with lactose intolerance.

- Horizon Organic – Offers organic cream products, including heavy cream ideal for baking.

- Kerrygold – An Irish brand known for high-quality dairy products, including cream that enhances baking.

- Golden Cream Margarine: baking cream which is made from vegetable oil, low saturated fats and has no dietary cholesterol.

- Organic Valley: Provides organic cream products, focusing on sustainable and ethical farming practices.

- Cabot Creamery:Offers a variety of dairy products, including cream that can be used in baking.

- Bulla Dairy Foods:An Australian brand known for its cream products, including those suitable for baking.

- Rebel Creamery:Specializes in dairy products, including heavy cream, often used in ice cream

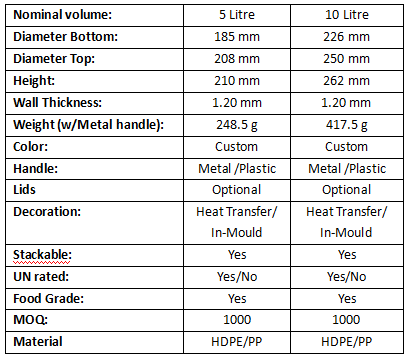

Specification

In conclusion, Innopack® 5L and 10L plastic buckets have many benefits. These features make them a great choice for packaging cream products.

Their durability provides reliable protection during storage and transportation. Their lightweight design makes handling easier and lowers costs. This is cost-effective, helping cream manufacturers save on packaging expenses.

The versatile sizes like 5L and 10L, cater to varying consumer needs. Their moisture resistance helps maintain product quality, and secure lids ensure freshness and re-usability.

Customization options through heat transfer printing enhance branding visibility, while compliance with HACCP/ FDA guarantees safety for edible products. With a growing focus on sustainability, many manufacturers are adopting recyclable plastic solutions, meeting consumer demand for eco-friendly packaging.

Trust the Innopack®’s professional plastic container OEM service, with friendly minimum orders and first-class customer service. These features make wide-open 5L and 10L plastic buckets great for the cream sector. They improve usability and efficiency throughout the product’s life.