Among all packaging technologies, plastic buckets/ pails owns the characteristics of high economic efficiency, wide applicability, and efficient transmission of brand LOGO information.

Some other packaging either too flexible that can’t carry big amount liquidation or too heavy protection material but high cost.

When you start to choose plastic bucket packaging for your goods, have you ever think what kind of labeling printing & decorating techniques for your plastic buckets? Or what kind custom logo printing methods are commonly applying on plastic buckets?

Today’s article will discover and top 3 custom decorating techniques in plastic bucket packaging: Silkscreen printing, Heat transfer printing & IML(in-mould labeling). It might help you to clarify which method can maximized your profits and performance better.

1. Silkscreen Printing

What is Screen Printing? It is a traditional printing process, which is by coating ink on the surface of the plastic bucket, and then using the screen to block the part that does not need to be printed, so that the ink can only be printed on the plastic bucket through the mesh of the screen.

The advantages of screen printing are simple operation, low cost, and suitable for mass production.

However, the disadvantage of screen printing is that the printing effect is relatively rough, and it is not suitable for the printing of fine patterns. Also the maximum colors mixture are within three kinds (1-3 colors)

2. Heat Transfer Printing

What is Heart Transfer Printing? Heat Transfer printing, as know as Thermal Transfer: it is a process in which patterned film is transferred to the surface of a plastic bucket by heat and pressure.

The advantage of thermal transfer printing is that the printing effect is clear, bright colors, and you can print a variety of complex patterns, including photo-grade images, smaller contexts and bar codes.

(photot: Innopack® heat transfer machine)

In addition, the heat transfer ink has good adhesion and wear resistance, water resistance and chemical resistance are also good.

However, the disadvantage of heat transfer is that the bucket wall will be left blank and not rich enough.

3. IML (In-Mould Labeling)

What is IML decorating? IML, also called In-mould labeling. It is a process which patterned film will fuse with bucket wall in injection molding producing . The patterned film need to be inserted in mould before injection. It brings the maximum utilization of bucket wall surface. In other words to say is real coating the whole bucket wall even lids.

The advantage is Fast Speed. This decorating integrate producing and decorating together in one step, which save producing time as a single unit. Moreover IML allows higher definition of picture, photo and context, the long durability and Unfading materials give people a feeling of lasting freshness.

The disadvantage of in -moulding label is that the decorating average cost is higher than the other two method.

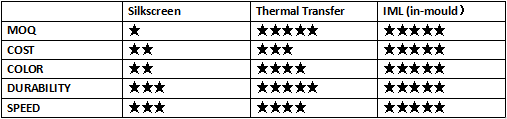

Comparison : Silkscreen vs Thermal Transfer vs IML

Here is a comparison table will shows you the differentiation among silkscreen printing, heat transfer printing and in-mould labeling. It is very intuitive to let you see clearly that you are choosing printing technology to bring you more convenience.

The process of Innopack ®’s customizing the LOGO of plastic products

Before the above Top 3 custom printing methods, customers need to provide the original HD logo file, such as HD JPG, PDF or AI format to us. The INNOPACK® team will first make a model for you, check the size and area of printing, and if you also need a real printed plastic product sample, we can provide pictures, videos or a delivery samples for the customer to confirm. After customer confirmation, we will print and start batch production according to the confirmed sample.

(photo: Stacking labeled plastic lids and buckets in cargo container for delievery.)

During the printing process, we will take photos or videos to record and update the production information to the customer in a timely manner. This way, you can see the custom plastic products before they are shipped. This also reduces errors in each process. Our considerable services will help you obtain the ideal plastic products that meet your requirements.

Through the above introduction, do you have a clearer understanding of the printing method of customized LOGO for plastic products? We hope to help customers choose a more suitable printing method for their plastic products. Finally, if you are still confused about the printing method, it doesn’t matter, just tell us your idea, we will provide you with a professional solution.

What Innopack® Can Help?

Our factory has more than 20 of the best equipment, including injection molding machines, raw material mixers and labeling paint machines, to improve product yield and style. We welcome OEM/ODM orders of any sized plastic buckets and pails includes lids and other plastic accessories.

Whether it is a lightweight custom project based on our existing products or the design of a new plastic product, we have the experience to create the ideal plastic product for you, from drawing production to sample production, discussing details, confirming orders, opening new molds, and finally going into mass production.