Plastic is one of the greatest inventions that affects the fate of mankind. 100 years ago, manufacturers understood that natural materials such as wood, amber, rubber, and glass were not ideal for mass production. This was because these materials were either scarce, expensive or not flexible enough. Synthetic materials are ideal substitutes, which can change shape under heat and pressure and retain shape after cooling.

Fifty years ago, the world made only a little plastic. Now, the world makes over 100 million tons of plastic each year to supply market demand. Each year, the United States manufactures a greater quantity of plastic than steel, aluminum, and copper.

Today, we will discuss two common synthetic materials used in making plastic buckets: PP and HDPE. PP stands for Polypropylene, while HDPE stands for High-Density Polyethylene.

Let me ask you a simple question, what factors will you consider in commercial packaging? A lightweight? Attractive labeling? a longer shelf life? Or a lower cost? you can find all the answers on plastic products.

Choosing the right material for injection molding buckets is important for several reasons. The raw material (resin) influences and dominates the durability, weight, cost, and suitability of buckets for its intended use.

Choosing the right material for a bucket is important for durability against stress, impact, chemicals, and extreme temperatures. It also affects the ease of manufacturing, as different materials have varying flow characteristics and cooling times, influencing production efficiency and quality. Additionally, selecting an appropriate material can enhance environmental sustainability by opting for recyclable or biodegradable options. Therefore, careful material selection is essential to optimize injection molded buckets’ performance, longevity, and cost-effectiveness.

What is Polypropylene?

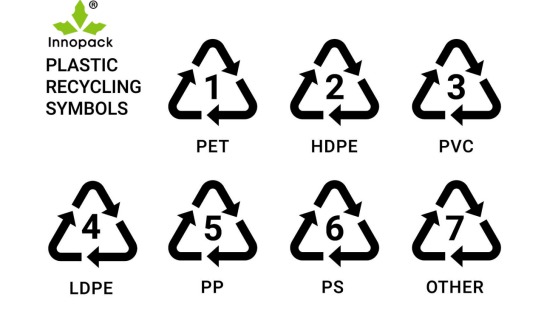

Polypropylene (PP) is a so-called Number 5! A thermoplastic material that owns a semi-crystalline structure. It extracts and processes from petroleum.

Polypropylene, a thermoplastic synthetic resin, boasts excellent attributes. It is a lightweight, colorless plastic with transparency, suitable for various uses. Its impressive features include resistance to heat and chemicals, electrical insulation, strong mechanical properties, and durability.

Chain growth polymerization can polymerize propylene into polypropylene. Polypropylene turns into long filaments after polymerization. The pelletizer cuts these filaments into pellets, and manufacturers can process them using injection molding techniques. Manufacturers can usually process polypropylene by using injection molding, blow molding, extrusion, and CNC machining.

Many industries use polypropylene for food containers, beverage bottles, gallon buckets, barrels, fabrics, and chemical process tanks. Polypropylene has excellent chemical resistance, is inexpensive, and has excellent fatigue strength.

A triangular recycling symbol can identify polypropylene with the number 5. See Figure 1 for reference.

What is HDPE?

This is Number 2 plastic: HDPE(High-Density Polyethylene). HDPE looks very close to PP(Polypropylene). HDPE comes from the family of the PE (polyethylene) group of plastics. PE also extends to LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), and UHMWPE (Ultra-High Molecular Weight Polyethylene.

HDPE is a highly crystalline, thermoplastic resin. The original HDPE looks milky white. Clear PE with a thin layer is highly resistant to chemicals in heavy-duty buckets for home and industrial use. This polymer is non-hygroscopic and has good vapor resistance.

HDPE is great for buckets and pails because it is resistant to corrosion, waterproof, strong, and prevents leaks. Transport chemical contents, oil, painting, etc.

HDPE material is very resistant to impacts, even at low temperatures like -40F. HDPE is a safe, colorless polymer that melts at 110-130℃ and has a density of 0.918-0.965. It is non-toxic and odorless.

It has good heat and cold resistance. This material is very stable and strong. It can withstand environmental stress and tearing. As the density increases, its properties improve. It is also resistant to acids, alkalis, and solvents.

Manufacturing Process in Injection Molding

Plastics are now used extensively in various areas of daily life and manufacturing, ranging from plastic bags and household appliances to computers, automobiles, and aircraft. Injection molding is a sophisticated manufacturing technique that involves melting, injecting, and solidifying plastic into a metal mold using a specialized hydraulic or electric machine. This process is crucial in creating plastic products with precision and efficiency.

Step 1: involves choosing the correct thermoplastic mold

Step 2: feeding and melting the material in (PP/HDPE/ Mixed )

Step 3: entails injecting the plastic into the mold, and

Step 4: focuses on the cooling process.

Step 5:ejecting and finishing the product.

Plastic parts are utilized across various sectors, including automotive, household appliances, and medical equipment, to safeguard, improve, and construct a wide array of products. Injection molding, known for its consistent and top-notch results, is a prevalent method for manufacturing plastic components. The injection molded plastics market is projected to experience a growth rate of 4.6% annually until 2028.

Advantages of PP

- Lightweight and flexible.

- Good chemical resistance.

- Lower melting point, which can reduce energy consumption during production.

- Cost-effectiveness in certain applications.

- Suitability for food-grade applications.

Advantages of HDPE

- High strength-to-density ratio.

- Excellent impact resistance.

- Superior durability and long-lasting performance.

- Better suited for heavy-duty applications.

- Suitability for food-grade applications.

- robust at winter lower temperature.

Recyclability and Environmental Impact

Unlikes other type material, Recycling concepts can easily understand from the symbols of PP and HDPE. Environmental considerations and the sustainability of each material. Green enterprise Innopack® is a global plastic container manufacturer and packaging who are utilizing and producing only 100% recyclable plastic products. In deed, Innopack® works on sustainable developing almost 20 years. Insights into recycling processes and how each material contributes to a circular economy please read our previous article on Innopack®’s plastic recycling.

In Innopack® plastic manufacturing and Packaging,we’d like to help you find the right plastic material in a batch producing your plastic pails, closure lids, and other accessories. If you have any questions or need more info. about plastic buckets please enquire us.