From this article you will understand the following:

What is a Robotic Gasket Dispensing?

How does robotic dispensing attach a gasket to a plastic bucket lid?

What are the advantages of using gasket dispensing in bucket lid productions?

Innopack® Bucket & Lid manufacturing

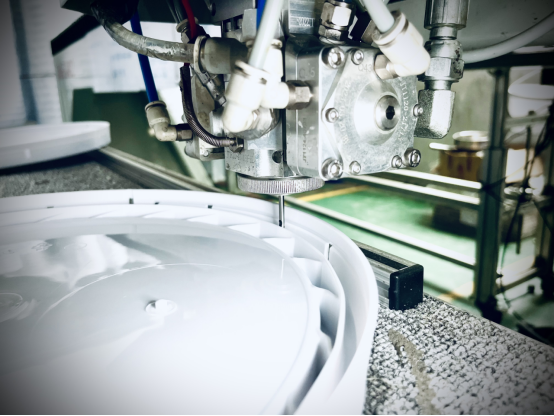

(photo: Robotic Dispensing gun extruding the liquid of making gasket)

Approximately Reading time: 4.5mins

Plastic Pails and Plastic Buckets are popular containers in modern commercial packaging. These containers can be used in any industry and are durable, leak-proof, and non-toxic. A plastic pail will have a compatible lid that qualifies as a shipping container, and a bucket is an open-top container commonly without a lid.

Higher quality and precise bucket lids are increasingly demanded for better transporting in safe

sealing and maintaining contents storing conditions. Equipment with mechanical automation in mass production can increase production capacity quickly. Only in this way can we meet the diversified customization needs of customers and the customization needs of plastic buckets and Lids.

Today Robots are becoming a new standard for dispensing applications due to their ability to follow an accurate path and apply a uniform coat of liquid material. let me show you how a robotic solution works in gasket dispensing processing, and how this new era of mechanical technology plays an important role in plastic bucket manufacturing and packaging.

What is a Robotic Gasket Dispensing?

Dispensing is a part of the industrial batch manufacturing process of gluing, sizing, coating, gasket, sealing, etc., A Dispensing machine is also known as a gluing machine which specializes in controlling the fluid flow, and the fluid drop, coating on the surface of the product or the product inside the automatic machine. It can achieve three-dimensional, and four-dimensional path dispensing, accurate positioning, accurate control, no wire drawing, no leakage, and no dripping.

A Gasket Dispensing Machine is mainly used for form-in-place dropping and coating gaskets on plastic bucket lids. In this product process accurately point, pour, paint, and drop to the exact position of each lid, which can be used to achieve dot, line drawing, round, or arc.

A Gasket Dispensing machine are working combined with robot arms , material pumps, regulators, and dispensing guns. Dispenser can apply different fluid materials such as sealant, adhesive, or polystyrene foam that can be formed and placed a gasket to standard plastic covers or tear strip lids. The extra o-ring gasket protects lids and open-head plastic buckets to integrate into one. For creating an air-tight sealed condition and leaking proof, Innopack® has significant experience in form-in-place gasket dispensing applications, particularly in the demanding plastic buckets lids and packaging market.

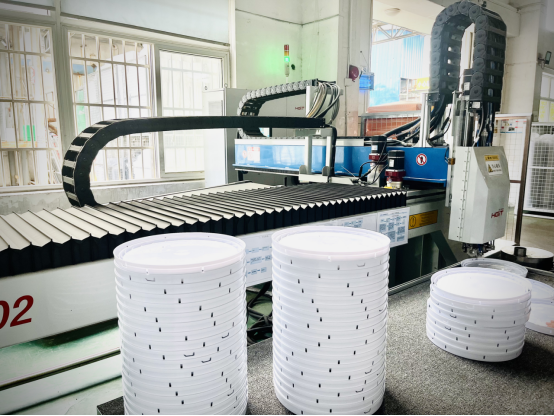

(image:Innopack® Robotic Dispensing Machine)

How does robotic dispensing attach a gasket to a plastic lid?

The updated o-ring gasket design is thicker and made of Polyurethane, unlike the original hollow replaceable rubber o-ring. It is fully robotic dispensing and attracting, eliminating the split-away-off lids that were a common failure point on the replaceable o-ring making it permanent durability and providing a longer-lasting air-tight sealing performance.

Innopack® plastic container manufacturer has upgraded the technology of a 3-dimensional axial robotic dispensing machine for attaching gasket O-rings. After inputting data CNC control system, the material pump pushes the two ingredients mixed from A tank and B tank, the air pressure pushes the material at, meanwhile the lids are placed up and down at the install area, and the robot arm starts to move by 3 axis directions to adjusting and aim precisely and the U- shaped gap. It will move a cycle that is lids side while extruding the liquid of the gasket, after then, during cooling it gradually sets for 3 seconds, and the gasket has been produced and attached to the lids. Innopack® air-powered bench top dispensers are perfect for automated plastic bucket lid manufacturing.

How does a 3-dimensional axis work:

- X-axis direction: left and right linear moving.

- Y-axis direction: forward and backward linear moving.

- Z-axis direction: vertically moving dispensing gun 5-8 mm above the lid.

(photo: lid with gasket and temper evident tear-off seal fits 3.5 gal plastic bucket)

Innopack® is convenient for workshop management and effective Benefits of Robotic Gasket Dispensing:

- Enhanced worker safety:First, protect innopack® worker’s eyes, The Robot can work in a haphazard environment, although the attached o-ring gasket is non-toxic, a big challenge for the traditional process needs you to precisely work on a tiny ring in the right place on the lids. Save labor’s Finger, using tools to attach a rubber gasket o -ring has a risk of finger cutting.

- Reduction in material waste:save glue, because of the high dispensing accuracy, you can ensure that there is no more glue, save a lot of glue, and waste a lot of glue when you manually point a lot of buckets and kettles.

- Increased accuracy:improve product quality, due to high dispensing accuracy, product pass rate increased a lot, improve the competitiveness of enterprises. the robot follows the data inputting,

- Higher production speeds. New-generation manufacturers are demanding the effectiveness of production. On one hand is cost-effectiveness which can lower the average cost of products, on the other hand, it saves time to make more orders by connecting with plastic Injection molding production of production. On one hand is cost-effectiveness which can lower the average cost of products, on the other hand, it saves time to make more ordersby connecting with plastic Injection molding productionimplementation of 7S management that makes the producing line a fast river flow.

- Consistency of dispensing:This problem is most common and intractable when producing small batches. About 44 % of customers said that because of the small batch production, they often use manual operations rather than automated robots. It becomes the biggest challenge to keep consistency between each handmade artifact of gasket installation. Since operators change all the time, it is hard to have consistency in bucket lid quality.

(photo: Innopack® Lids fits 5 gal plastic buckets)

Innopack® Bucket Lids

The invention of the dispensing machine is a great process, the Innopack® plastic buckets and lids manufacturer leads the world’s plastic production enterprises and can manufacture 5000 different sizes and colors of plastic bucket lids every day such as Gamma seal Lids, tear-tap easy-off lids with a tamper-evident seal, screw bucket cap, and lids with spout. dispensing gaskets o-ring on lids to ensure the sealing of each plastic with the lid, durability, consistency of high quality. It is being sought after by more and more global customers.

Disclaimer:

The Innopack® Manufacturer offers all information as a general guide. It is the customer’s responsibility to select the adaptive buckets, lids, and accessories for your products and use them in application compatibility. The Innopack® does hereby disclaim all warranties, described or suggested, and implied warranties to be merchantable or suitable for particular purposes or applications. We are not responsible for consequential damages that may arise from the customer’s selection and use of buckets, containers, accessories, pail lids, and labels.