The durability of packaging materials is very important in sectors like building, chemicals, and food packaging. The 20L plastic bucket is one of the most common containers because it can be used for many things and is strong. But the real test of a bucket’s reliability is how well it can handle being hit while being moved, shipped, and used every day. This is where the drop test is very important.

Plastic buckets like 20-liter or 5-gallon ones are used for a lot of different purposes, from carrying food to keeping chemicals, so they need to be extremely sturdy. If a bucket breaks after being dropped, it could damage or contaminate the product or even pose a safety risk in an industrial setting. So, a drop test is crucial to make sure that the object can keep its contents safe when it’s under stress.

(Photo: Innopack® Drop Test Stair is up to 2 meters height)

Heavy drop tests are an important part of quality control for packaging manufacturers like Innopack®. Not only does it help them make sure that their plastic buckets work, but it also makes sure that they can handle rough handling without breaking. Knowing how important these tests are makes sure that customers get reliable, high-quality buckets that work well in real life.

What Is a Drop Test?

A plastic bucket drop test is a way to see how well a plastic bucket can handle the drops and falls that happen all the time when it is being moved and handled. Manufacturers can check to see if their product is strong enough to avoid cracks, leaks, or deformation by mimicking these conditions in a controlled setting.

There are 4 main Purposes in this Plastic Bucket Drop-Test (BASE):

- See if a Plastic bucket lid is still sealed after suffering an impact

- See if a Plastic Bucket Body Leaking

- See if a Plastic bucket’sbottom is strong enough to support the structure.

- See if a Plastic Bucket Handle was broken

Test Parameters for a 20 Litre Bucket

The drop test for a 20-liter plastic bucket checks whether it can withstand different types of impact. One of the most important parameters is the drop height, usually set to a standard range of heights between 0.8 meters, 1.2meters and 1.8 meters to model how things are handled in real life. At these heights, you can imagine what it would be like to fall during shipping or stacking in a warehouse.

The direction of the bucket during the test is another important factor. Buckets are dropped on their side, edge, and base to see how well they handle being hit from different directions. This helps figure out if the bucket is more likely to break in certain positions.

Lastly, key factors for judging durability are the number of drops and the number of times they happen. People often drop buckets more than once to see how well they hold up after being hit many times. This keeps the bucket from breaking, leaking, or deforming over time even if it is rough-handled. These tests help companies make sure that their buckets are tough enough and reliable enough to meet high standards.

Perpetration of Innopack ® 20L Buckets Drop Test

On December 9th 2024, Innopack® Manufacturer Suzhou Co,.Ltd Quality Control Team made a 20 Litre Plastic Bucket Base Drop Test. Here is a perpetration tool list what we made:

- Electronic Scale( weight measure) x 2

- PP 20 Litre Plastic Buckets x2

- PP 20 Litre Plastic Lids x2

- Laser Distance Meter x 1

- Steel Portable Stair x 1

(Photo: Left Red 20 L Pail fully loaded 20.376 KG water, Right Yellow one is 20.297 KG )

How to Do a Drop Test

(20L /PP/ Plastic Bucket/ Base direction)

Here is a simplified process of how we do a base direction drop test for an Innopack® 20-liter Plastic bucket:

- Marked buckets with lids into Sample 1 & Sample 2

- Measure the empty bucket weight of both Sample 1 & 2 and write down the data

- Fully Filled Water into 2 buckets

- Measure the Fully Loaded weight of both buckets

- Measure Drop Height 1.0 m & Base Direction Drop Vertically

- Rolling bucket on the floor to check damage & record

- Measure Drop Height 1.2 m & Base Direction Drop Vertically

- Rolling bucket on the floor to check damage & record

- Measure Drop Height 1.8 m & Base Direction Drop Vertically

- Rolling bucket on the floor to check damage & record

20 L Plastic Bucket Drop Test Result

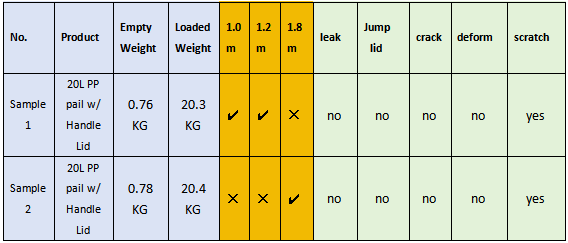

By following the drop test steps shown above, we write down the test data in the following table.

(Innopack® 20L,PP Plastic Bucket Drop Test Table 1.1)

Leakage Proof

According to the drop result, Table1.1 shows, that when fully loaded liquid (Water) Both Samples Drop from range1.0-1.8 m vertical height doesn’t occur Leaking which shows the sealed condition could maintain good Sealed condition from a strong impact even dropping from 1.8 meters.

Secured Tamper Evident Lid

Vertical drop on the floor doesn’t make the lid “jump up”, as we know the height of 1.8 meters gives a strong up force once the base touches down to the ground. Both samples 1,2 have a great sealed tamper-evident lid that stays attached to the bucket after the test.

Best Resilience

Table 1.1 and Slow Motion from the test video shows that when the 20L bucket is full and falls from the 1.8-meter high platform, the plastic bucket of PP material can maintain the cylindrical barrel body very well, and does not make it deformed and cracked. This is good proof that the high flexibility and resilience of the plastic bucket can protect the transported items well even if they are hit by external forces or fall vertically during transportation, they can still protect the items themselves to maintain in the sealed bucket.

Strong Buckets, Strong Innopack®

Drop Testing is one of the most common method to prove a good durable 5-gallon or 20-liter plastic bucket. It ensure that these lid-covered plastic containers can handle being transported roughly and accidental impact they may face in different sectors.

Picking strong buckets is important for keeping your goods safe. Innopack® makes sure that their bulk plastic buckets meet the highest performance standards by testing them thoroughly.

If you need strong, reliable packaging options, please don’t miss any of Innopack®’s carefully produced buckets.

Get in touch with us today to get a surprised lower price. Or visit our website to find out more about Innopack®’s fun testing methods and how their Plastic / Metal buckets can help your business.