We have discussed the cost-saving strategies in plastic bucket packaging by innopack® plastic container manufacturers. How to provide economic effects, and innovative, high-quality product packaging had become the key to winning more profits due to a competitive market.

Plastic container packaging originally appeared in the early 20th century, with the development of plastic technology, especially the maturity of plastic injection molding technology, the production cost of plastic containers has been greatly reduced, which has promoted its wide application.

plastic buckets as packaging methods can be universally used in Food, Medical, Construction, Agriculture, Auto Decoration Beauty, and other Chemical Industries. Today let me lead you to 6 functions of plastic bucket packaging, you will finally find out why plastic buckets can be the most successful packaging to deliver value and confidence to your potential customers.

Function 1: Protects The Products

Most goods need physical protection in their packaging. Good packaging is required to maintain the good quality of wrappage, which is not easily damaged during transportation and storage. Moreover, packaging also needs to protect the interior from being polluted by the external environment such as dust, moisture, and temperature. Imagine a hot summer day when you

open up a melted chocolate bar from a soft package and mess up your fingers and clothes. We always want to find a better clue to maintain product quality for customers.

(photo: non-toxic plastic bucket packaging can be reused in DIY application)

Plastic buckets can protect goods well and safely, and the high-density materials of Polyethylene can support the bucket’s stable molecular structure which provides sturdy protection. Polypropylene(PP) is another resin to make buckets, with a more flexible solid material that owns better elasticity and creates a great impact resistance from moving, dropping, and scratching.

Due to its high-temperature resistance chemical properties, both PP/ HDPE Plastic pails allow filling up to approx. 85°C. Users won’t consider melting and deformation in summer or high-temperature environments. However even if plastic buckets can perform excellently in hot, it doesn’t mean plastic buckets are fireproofing.

Function 2: Convenience

A customer’s favorite packaging always delivers the customer a value of ‘convenience’. imagine you shopped for 10 different products from the supermarket, the final product you paid additionally is a plastic bag, which is a soft container for all the products you just bought. Have you ever thought this way, all you need from this plastic bag is a bigger container and a handle right? What makes you willing to buy a plastic bag after all the shopping? The answer is ‘Convenience’.

Plastic buckets with handles can delivery more convenient to carry, lift, transport, ship, and even when you use plastic such as pouring liquidation from the buckets. A galvanized steel wire handle or plastic handle with an ergonomic fingerprint grip. Both of this two kind handles are commonly attached to buckets.

Function 3: Differentiate Product

In the fierce competition in the market economy, thousands of companies are producing and selling similar products, such as car brands the world to reach thousands of, then more simple products may be more, so through packaging to distinguish the same type of products stand out on the shelf, it becomes particularly important.

Plastic bucket packaging is known as advanced packaging, It has the same size, and neat appearance, and is ready to pick up. Attractive packages surely help your products stand out and attract customers towards it. Using a unique color and decoration can make customers easily identify and differentiate your brand from other products.

(photo:In-mould labeling synchronously completed in production)

Function 4:Contributes To Product Market Strategy

Using a bigger than just fine capacity packaging is always can get more profits. Customer repurchase rate is a big challenge due to a competitive economy. Simply explain this market strategy is bigger sized means buy more, it doesn’t mean waste or over purchase. To lock in first-time buyers and more profits, you want to keep our customers but won’t let them jump to another brand for similar products.

An example is 3 bottles of shampoo bundled together for sale, it’s not a waste, you just purchased 2 extra for future use. It reduces the customer’s jump to another brand after using only one bottle. You let your customer stay and use it for a longer period at an attractive promotional price.

Plastic buckets do play a good market strategy too. Innopack® offers from 1L-30L different volume capacity plastic bucket. The most popular sizes are 5 gal plastic buckets and 20L plastic buckets, why? Because of the size, it is just fine to reach the optimized profits. For the capacity of 20L, it gives the merchants more goods quantity per packaging and reduces total cost by decreasing the number of packaging goods such as coatings, grains, fertilizers, chemical solvents, adhesives, etc.

Function 5:Information Transmission

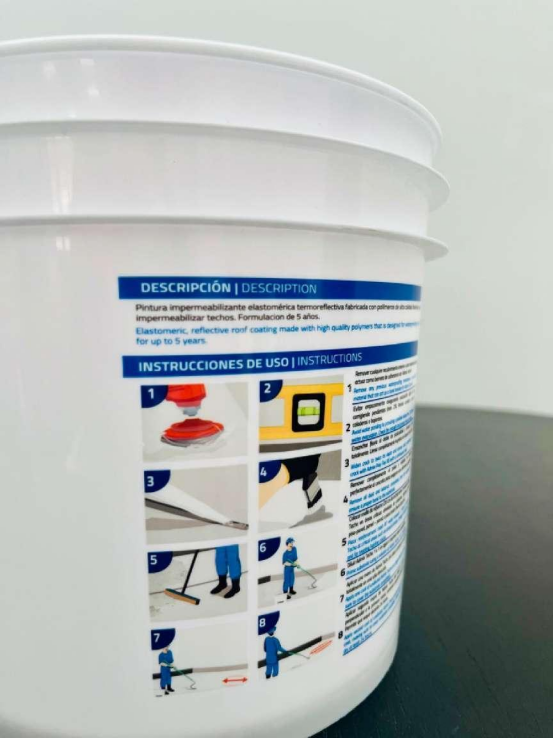

If you decide to use plastic buckets as commercial packaging, labeling is another essential tool to make customers aware of products’ feature directions , storage manuals, information on ingredients, warning signs, and other bar codes or QR codes.

(Photo:Innopack®’s high definition label decorating)

Plastic bucket packaging supports a bigger decorating space than other soft packaging, the bucket walls are your innovative canvas, it can be decorated by using heat transfer printing, in-mold labeling, screen printing, or tickers. It’s flat, clear, high definition, easy to look, and never peels off. For example, the innopack® 20L plastic bucket can print your label requires approx. 1500 cm² bucket wall areas.

Function 6:Security

For security considerations, make sure no tempering with the original product packaging is necessary. Unlike flexible packaging uses heat-sealed technology, in plastic bucket packaging, we use a tear tab lid with temper evident sealed to ensure the first touch principle to create ‘safety’ and ‘confidence’ for customers.

Tear Strips are molded and produced on a lid which is easy to peel off and gives an additional gasket O-ring to make sure the whole plastic bucket is proof.

Innopack® also provides reusable lids after the first time opened: Gamma Sealed lids which a screw-able lids with an enhanced bucket open head nested design.

(photo: Innopack®’s injection molding producing 5 gal plastic buckets)

Types of Plastic Bucket Packaging

- Round plastic buckets with lids

- Oval plastic buckets with lids

- Square plastic buckets with lids

- Rectangular Plastic buckets with lids

- UN rated / Not UN rated

There is no doubt that plastic bucket as a product packaging is high-grade, durable, attractive, and eco-friendly. In addition, with his 27 years of experience in injection molding and professional packaging, INNOPACK® has helped more than 100 companies around the world complete one-stop services from manufacturing to printing. If you have any ideas, please send them to us.